Comprehensive testing of explosion-proof equipment according to standards EN IEC 60079 and UL 746C

-

Accreditation in accordance with standards ISO/IEC 17025:2017, ISO/IEC 17065:2012

-

Specially equipped laboratory for conducting complex tests on all types of explosion protection

-

Unique challenges for Ukraine and the world

-

20+ years of cutting-edge experience of our experts in the industry

-

Objective test results at affordable prices

-

Significant savings in costs and time when testing at the research sample stage rather than at the mass production stage

Competent authorities

ATEX testing

Explosion-proof equipment

Service provider

ТОВ “ЦВВО” – одна з небагатьох організацій у світі, які можуть проводити оцінку відповідності вибухозахищеного обладнання. Ми призначені та уповноважені Міністерством економіки проводити роботи з оцінки відповідності обладнання та захисних систем, призначених для використання в потенційно вибухонебезпечних середовищах, на території України та ЄС відповідно до стандартів ISO/IEC 17025:2017, ISO/IEC 17065:2012

All unique tests

Standards

Testing in accordance with the requirements of the Technical Regulation for Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres (ПКМУ № 1055 від 28.12.2016) and Directive 2014/34/EU (ATEX). Testing according to EN IEC 60079 to confirm that the equipment will not become a source of ignition in an explosive atmosphere, which is critical for petrochemicals, metallurgy, energy, mining, etc. Testing of explosion-proof equipment for resistance to prolonged exposure to ultraviolet light and water in accordance with UL 746C.

Leave a request for a consultation

Describe your request and our specialist will contact you shortly to provide detailed advice on certification, conformity assessment or product labeling in accordance with Ukrainian and EU requirements.

Testing of explosion-proof equipment

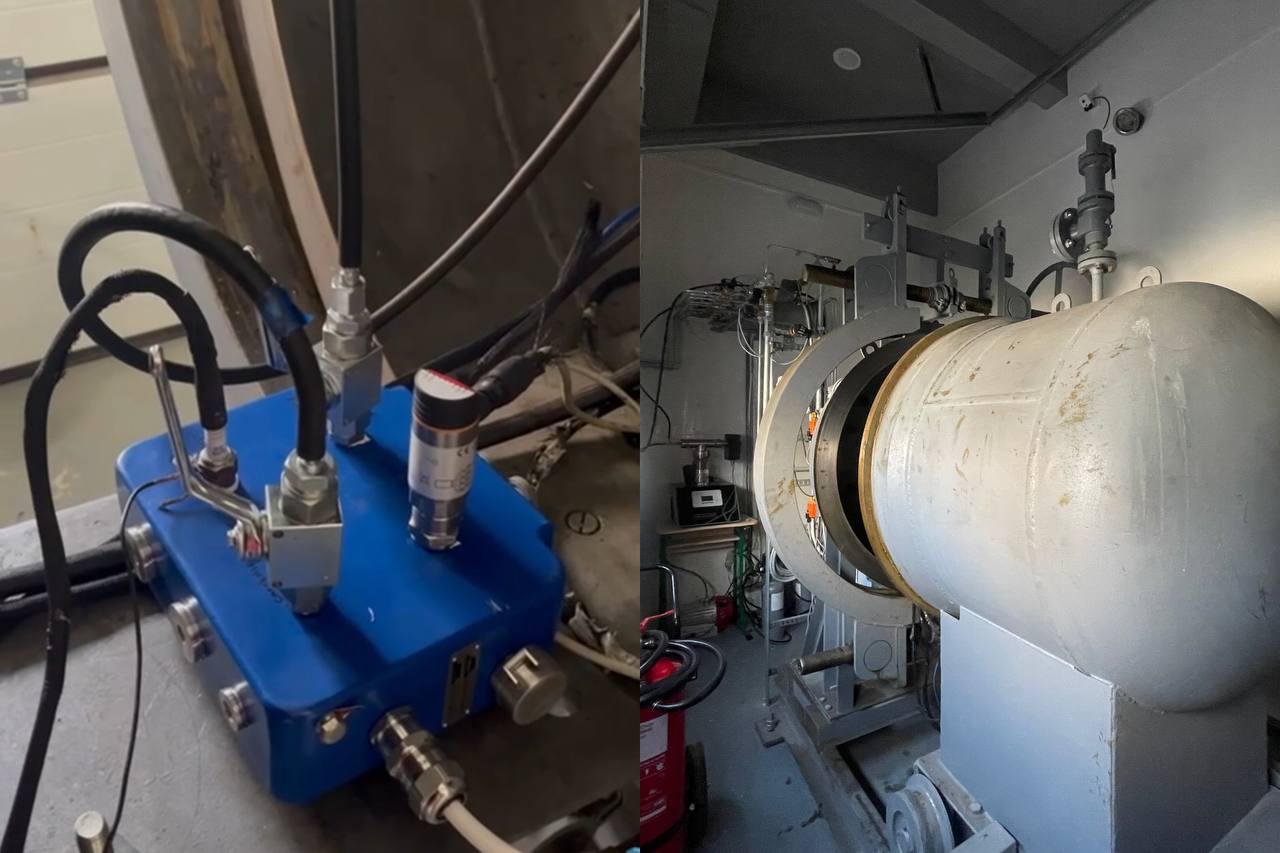

Explosion-proof equipment is used in all industries, manufacturing, and technological processes where explosive atmospheres are present or may be present. Depending on the type of explosive atmosphere present in a given location, different types of explosion protection are used in equipment, and accordingly, different requirements apply to them, and different approaches are used to assess the conformity of such equipment.

In Ukraine, as in the rest of the world, there are mandatory requirements for equipment used in potentially explosive atmospheres. These are the Technical Regulations for Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres No. 1055. This resolution of the Cabinet of Ministers of Ukraine contains requirements for the modules used during conformity assessment, depending on the explosive environment in which the equipment will be used and, accordingly, the type of explosion protection it has.

The cost and complexity of testing and conformity assessment of explosion-proof equipment depend on several key factors:

1. Environment of operation.

Equipment requirements are determined by the composition of the explosive atmosphere (gas or dust mixture, auto-ignition temperature, etc.) and the area of application — from mining equipment to machinery for gas or dust environments.

2. Zone classification.

The higher the risk level (an area where an explosive atmosphere is present continuously or periodically), the stricter the requirements and the more extensive the conformity assessment procedure.

3. Equipment type.

Simple equipment (such as lamps or junction boxes) requires less expertise. At the same time, complete installations — combines, pump units, lifting machines, fuel dispensers — require comprehensive technical expertise, which makes the process longer, more complex, and more expensive.

Based on the results of certification tests and trials, a test report is drawn up, which is one of the grounds for the conformity assessment body to decide whether to issue a certificate of conformity.

Our advantages

NAAU accreditation according to DSTU EN ISO/IEC 17025:2019 and a full range of tests for all types of explosion protection

Specially equipped and furnished premises for conducting tests with automated results delivery processes

Best practices and high competence of specialists in each area of explosion protection testing

Guaranteed real test results, maximum accuracy and reliability

Our bodies are among the few international centers authorized to conduct conformity assessments of explosion-proof equipment.

Continuous research and development and constant improvement of testing processes

Technical regulations for testing explosion-proof equipment

- Technical regulations for equipment and protective systems intended for use in potentially explosive atmospheres (Resolution of the Cabinet of Ministers of Ukraine No. 1055 dated December 28, 2016)

- Directive 2014/34/EU (ATEX)

Equipment and protective systems intended for use in potentially explosive atmospheres

Types of tests for explosion-proof equipment

- Drop test

- Heat shock test

- Small parts ignition test

- UV and water resistance

- Impact test

- Torque test for bushing insulators.

- Mechanical resistance of transitions, cable connections, plugs

- Heat resistance test

- Cold resistance test

- Testing the resistance of Group I electrical equipment to the effects of chemicals

- Checking the integrity and continuity of grounding

- Determining the surface resistance of non-metallic parts of enclosures

- Capacitance measurement

- Verification of fan ratings

- Charge transfer test

- Electrostatics. Hazardous manifestations

- Alternative tests for elastomeric sealing rings

- Typical impact resistance test

- Marking and instructions

Types of explosion protection

- Type of explosion protection: increased safety “e”

- Type of explosion protection “n”

- Type of explosion protection: “sealing ‘m’

- Type of explosion protection: explosion-proof enclosure “d”

- Type of explosion protection: “enclosure under increased pressure ”p”

- Type of explosion protection: quartz filling of the enclosure “q”

- Type of explosion protection: liquid filling of the enclosure “o” and structural protection

- Type of explosion protection: intrinsically safe electrical circuit “i”

- Type of explosion protection: “structural safety protection” ‘c’

- Type of explosion protection: “ignition source control protection” ‘b’

- Type of explosion protection: “immersion in liquid” ‘k’

- Type of explosion protection: “protection of equipment” and transmission systems using optical radiation

- Type of explosion protection: electrical equipment with explosion protection level (EPL) Ga

- Type of explosion protection: explosion-proof electrical resistive distribution heating

Cost of testing

The cost and complexity of such tests and conformity assessments depend on the zone and composition of the explosive atmosphere, as well as the type of equipment and type of explosion protection.

The more complex the type of explosion protection, or the combination of several types of explosion protection, the more extensive the requirements and the verification of these requirements for products, the scope of testing and technical expertise. This determines the cost of testing and conformity assessment of equipment and protective systems intended for use in potentially explosive atmospheres.

For an initial analysis of the scope of work and determination of the conformity assessment procedure, it is MANDATORY to know the explosion protection marking of the equipment, as well as to have a general description of the products, nominal characteristics, photographs, drawings, and electrical diagrams. Our specialists will review your request and technical documentation and quickly and efficiently answer your questions, as well as help you choose the conformity assessment procedure for your equipment free of charge..

You can contact our providers directly:

.

1. Testing laboratory ТОВ “ЦЕНТР ВІДПОВІДНОСТІ ВИБУХОЗАХИЩЕНОГО ОБЛАДНАННЯ”

Based on the test results, we provide a TEST PROTOCOL

It contains the following information:

- Title and details of the testing laboratory (including accreditation);

- Protocol number and date of compilation;

- Details of the customer ordering the tests;

- Product name;

- Product type, model, serial number;

- Manufacturer and/or supplier;

- Date of receipt of the sample by the laboratory;

- Name of the Technical Regulation or standard according to which the test is carried out;

- List of methods and standards used;

- Test conditions (temperature, humidity, voltage, etc.);

- Measuring instruments (with calibration details);

- Detailed data for each test item (e.g., electrical strength test, protection against electric shock, resistance to overvoltage, etc.);

- Measured actual values and their comparison with acceptable standards;

Comments or observations (if any); - Overall test result (complies/does not comply with requirements);

- Remarks or recommendations (if any);

Signature(s) of the responsible person(s) and stamp (if applicable).

We have prepared answers to frequently asked questions from customers.

1. Electrical equipment: distribution cabinets, lighting fixtures, motors, sensors, switches, automation devices.

2. Mechanical equipment: gearboxes, pumps, fans, mixers, compressors, even if they do not have electronic components.

3. Protective systems: devices or components designed to stop an explosion or limit its impact (e.g., explosion relief valves).

4. Components that do not operate independently but are designed to be integrated into explosion-proof equipment.

5. Control and diagnostic systems that ensure safe operation in areas with explosion risk.

Equipment is classified into groups (I, II, III) and categories (M1/M2, 1/2/3) depending on the level of explosion protection and the area of application. If your equipment is intended for use in oil refineries, chemical, pharmaceutical, agricultural enterprises, elevators, or mines, it is most likely subject to the requirements of this regulation.

– Conclusion on compliance with the standard;

– (if necessary) recommendations for further refinement of the design or materials.